- Wall Curing Agent Adhesive

- Stone like Paint

- Interior Wall Paint

- Colorful Paint

- Latex Paint for Exterior Wall

- SBS Liquid Coil Polyurethane Waterproof Coating

- RG Waterproof Coating

- Waterborne Polyurethane Coating

- Ceramic Tile Adhesive

- Transparent Waterproof Adhesive

- Compound Adhesive

- Waterborne Industrial Paint Emulsion

- Coating Additive

- Rust Converter

- Rust Stabilizer

- Sand Fixing Agent

- Pressure-sensitive Adhesive

- VAE Emulsion

- Textile Emulsion

- Waterproof emulsion

- Architectural Emulsion

0102030405

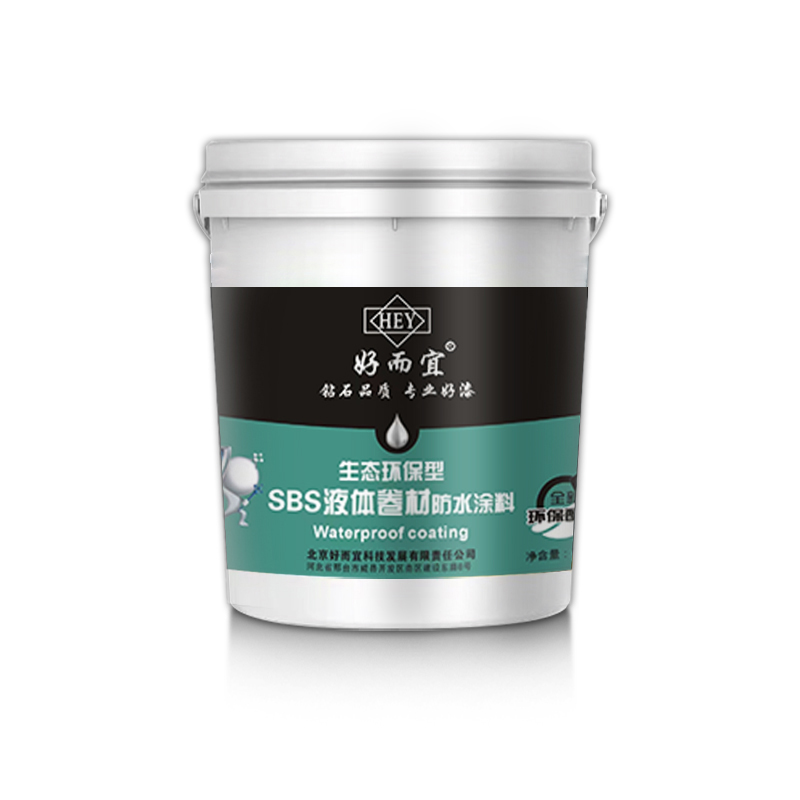

SBS Liquid Coil Polyurethane Waterproof Coating

description2

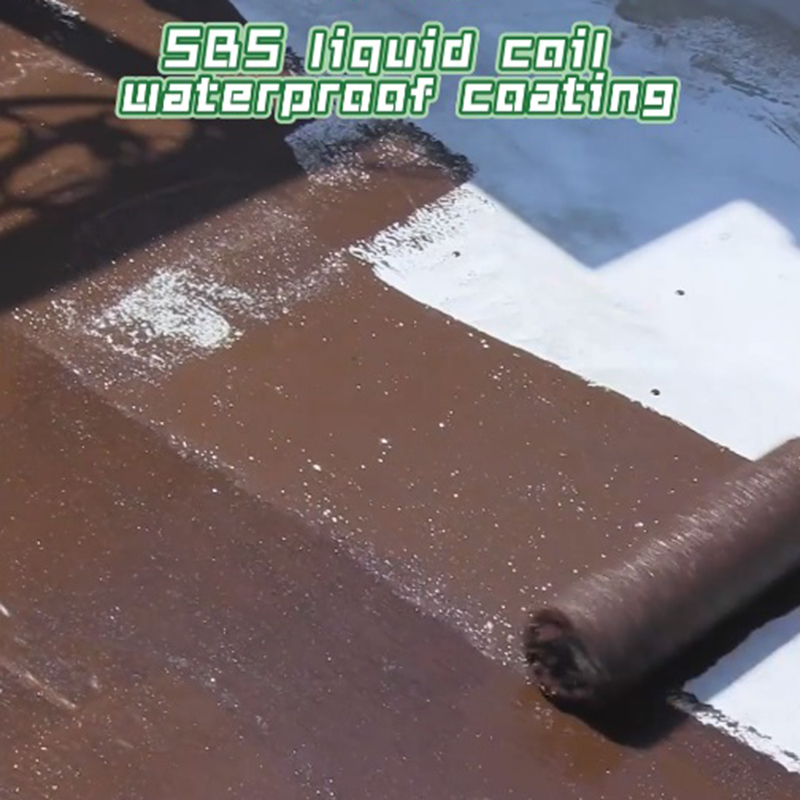

video

Application

It is applicable to the waterproofing work of surface and facade for various buildings made of cement, brick,stone and metal etc.

Product Display

Characteristic

1.It is easy and safe to use, no need of heat source,low odor without coal tar.

2.It is environment-friendly, low odor without coal tar.

3.With aging resistance and high elasticity, it can self-repair,especially suitable for the waterproof of the structure easy to crack and deform. It can form an integral jointless sealing layer, even if there is damage to the waterproof layer in the future, you can have it repaired without destroy the waterproofing effect of the whole waterproof layer.

Package: 18kg/bucket

Direction for Use

Construction tool: rolling brush or brush.

Open the package of the bucket, if there is a floating layer,mix and stir it evenly, then ready for use.

Preparatory work before coating: clean the surface dust and sundries, remove the loose parts and sharp points, make the base surface flat and firm, the product cannot be used if the base surface efflorescence degree is high or there is obvious water.

Number of brushes: Generally 2 or 3 times, brush again if the previous coating is dry enough and not stick to hand.

Usage amount: Theoretically 1.5-2kg/㎡,the actual amount will vary depending on the method of use and the roughness of the surface.

Storage: Store in a dry and cool place, the environment is around 5~40℃

Construction condition: Construction is prohibited outdoor in rainy,snowy and windy weather, the environment temperature should be around 5~35℃.

Shelf life: 12 months.If it exceeds the shelf life, it can still be used after inspection.

Reminder:

1.Clean all tools promptly with water after coating work is finished or stopped.

2.The ventilation conditions should be good at the construction site.

3.The lid of the bucket must be tightly closed, keep it out of the reach of children. In case of eye contact, wash with water immediately.

4.The product does not contain toxic gases and mercury.

5.Do not pour the remaining unused product down the drain or exhaust pipe.